In our constant ambition to become even better and more efficient, we work with automation and robotization in a program launched a while back. Now the turn has come to a new article and the production has begun. We work based on the basic assumption that when a tool can be run smoothly, the customer's demand is for the "right" volume and there is a sufficient horizon for the product's lifespan, then it's time to automate. In this case, we even saw this volume around the corner and when the customer indicated increased volumes last year, we started the project.

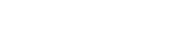

A concept we have used successfully in the past is to "build in" an existing machine and operate it with a robot. Nothing unique or patented but a successful factor for us. It becomes sustainable as we recycle equipment we already use and we can quickly switch from robotic service to manual service of the machine. It increases our utilization rate of existing equipment. So sustainable in this aspect as well.

You can see on the pictures that we have reached the construction phase of this project, and we expect to start the automated production shortly. The entire project is led and managed by internal resources from our production of technology. This means that we also "build in" knowledge in this case. Over time, it has proven to be a good solution as we quickly can respond and untie knots that have arisen from disturbances or modifications of the product.

To be continued...